India is one of the rare countries, where the estimated bottle collection is in the range of 80-90%.

AeroFibre’s Legacy:

We are proud to say that we are third generation into the plastic waste business. In the late 80s, my grandfather started in the recycling and processing of PET industrial waste. In 2008, my father commissioned the fibre recycling plant to further process the industrial waste. After completing my graduation in UIUC, I decided to join the family business in 2009. I was excited about the recycling of polyester waste and elected to head this business. In 2017, we commissioned a state-of-the-art recycling plant that has the capacity to process 18,000 M.T.A. of hollow and hollow conjugate fibre.

We are the first company in India to have 2 German bottle sorters in our wash-line. Our main focus was to enhance the quality of flakes which will result in higher fibre quality.

In 2021, we realised that there was an increasing demand for high quality flakes for bottle to bottle and bottle to filament segments; and there was a paucity of good quality PET flakes in the market. To fill this gap, we have installed an advanced laser sorting machine from Germany to process flakes which are as clean and consistent as diamonds – hence our brand DiamondPET Flakes!

Our DiamondPET flakes provide a consistent high total purity value of less than 100 ppm. We create this with the help of dual automatic bottle sorters, manual sorting as well as a final check with an automatic laser sorter. Just like high pressure makes diamonds, we employ heat washing and pressure sorting to make diamonds out of trash.

Our team

We have a team that is 150 strong today who work on 3 shifts to produce PET flakes that are of precise and consistent quality. We have installed an effluent treatment plant to reuse and recycle all our water used in the PET flake production. Our plant qualifies as a zero liquid discharge site. We also generate a portion of power needs via Solar power.

The future

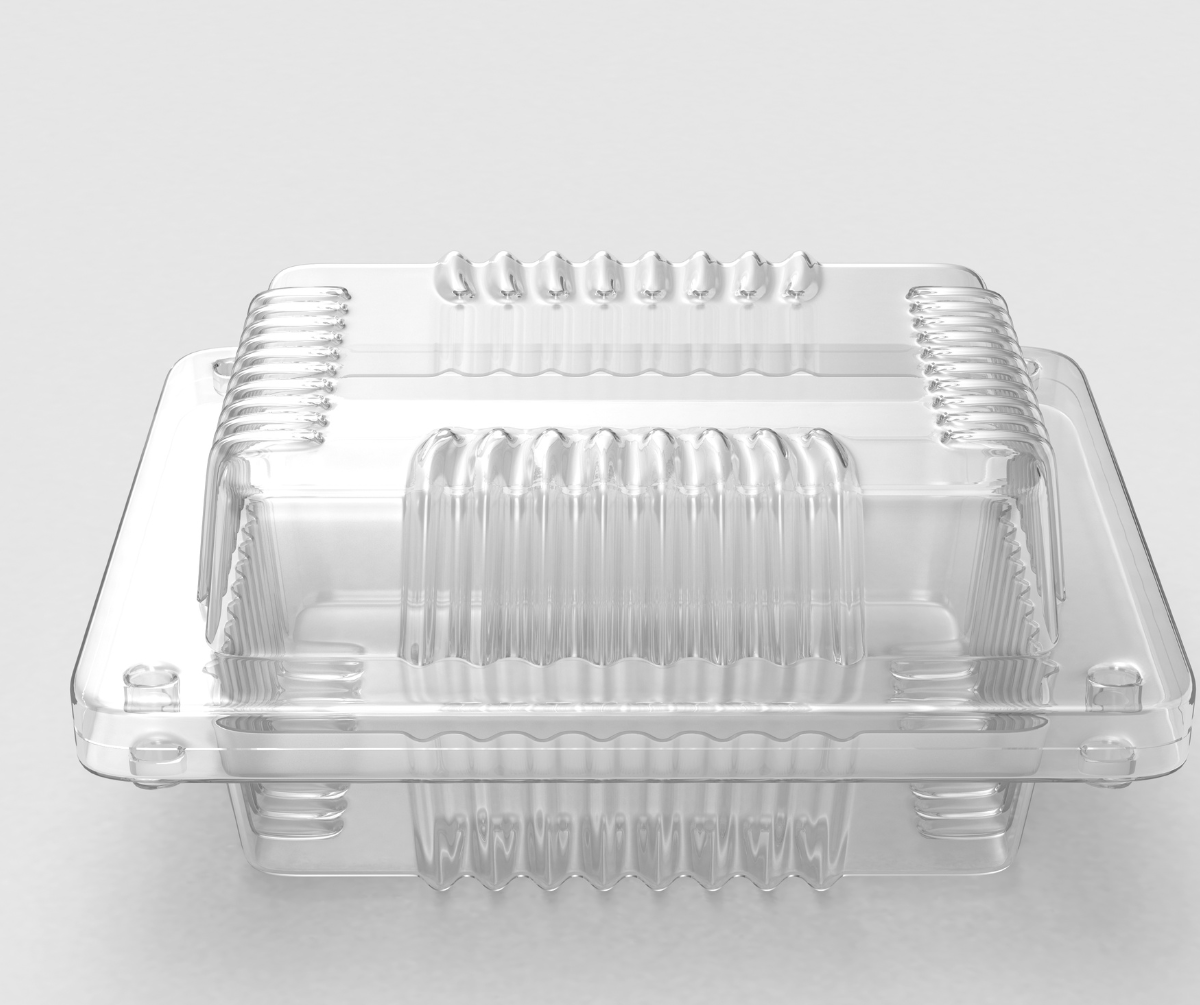

Our goal is to produce high value products from plastic waste. To that end we want to process as much of the by-products generated while processing the PET bottles – from segregating caps and wrapper, we now wash and produce granules that can be made into injection moulded products like crates and other items.

Conclusion:

At AeroFibre, we want to produce the best value for our customers, treat our team as family and give back to the communities that we are a part of. We believe in doing well by doing good. Hopefully, one day in the near future, we will be part of the reason India will be able to recycle 100% of plastic waste, creating value from waste.

Article published in the PET Planet Insider magazine, October 2021 edition.