Your Complete Guide to rHDPE

As sustainability becomes increasingly important worldwide, more focus is being put on plastic recycling - transforming used plastic into valuable raw materials. One such recycled plastic gaining significant traction is rHDPE, or recycled High Density Polyethylene. But what exactly is rHDPE and why does it matter? Let’s dive in and understand this fascinating recyclate!

What is HDPE?

HDPE, or High Density Polyethylene, is one of the most commonly produced plastics globally. With its high strength-to-density ratio, excellent chemical resistance, easy processability and low production costs, HDPE finds widespread application in bottles, containers, pipes, sheets and films.

According to Plastics Europe’s report, HDPE accounted for over 18% of global plastic demand in 2019. From your plastic shampoo bottles to milk jugs, laundry detergent containers and pipes transporting drinking water - HDPE is indispensable in modern daily life.

Enter - rHDPE

rHDPE, or recycled HDPE, is produced by recycling post-consumer HDPE waste like bottles, containers, plastic bags etc. Instead of leaving used HDPE to occupy landfills for up to 1000 years, recycling gives it renewed purpose in second-life applications. This circular model allows sustainable resource use while cutting down on waste.

Via processes like sorting, washing, shredding and agglomerating plastic waste, recyclers are able to reform usable rHDPE resin tailored to given specifications. As technology progresses, the quality and versatility of rHDPE continues to reach new heights.

Benefits of rHDPE

Some key benefits that are driving adoption of recycled HDPE resin are:

- Significant energy savings over virgin HDPE production

- Reduced carbon emissions and waste directed away from landfills

- Plastic waste given useful second life instead of leaking into ecosystems

- Helps brands, manufacturers attain sustainability goals

- Supports development of recycling infrastructure and circular economy

Uses of rHDPE

From non-food containers to pipes, decking, road barriers, automotive parts and even park benches - rHDPE is closing the loop with its reliability and safety across constructions, packaging and innovative products.

As technology and processing improves, rHDPE is also being used in advanced applications like 3D printing and high-stress mechanical parts. This expands its versatility even further.

The Future is Circular

With its environmental upsides, increasing quality and broadening usage spanning daily and complex applications, recycled HDPE resin is key to transitioning economies to responsible plastic use. By utilizing waste we reduce virgin plastic dependency. By recycling better, we squeeze productivity out of every scrap. The circle indeed holds endless possibility.

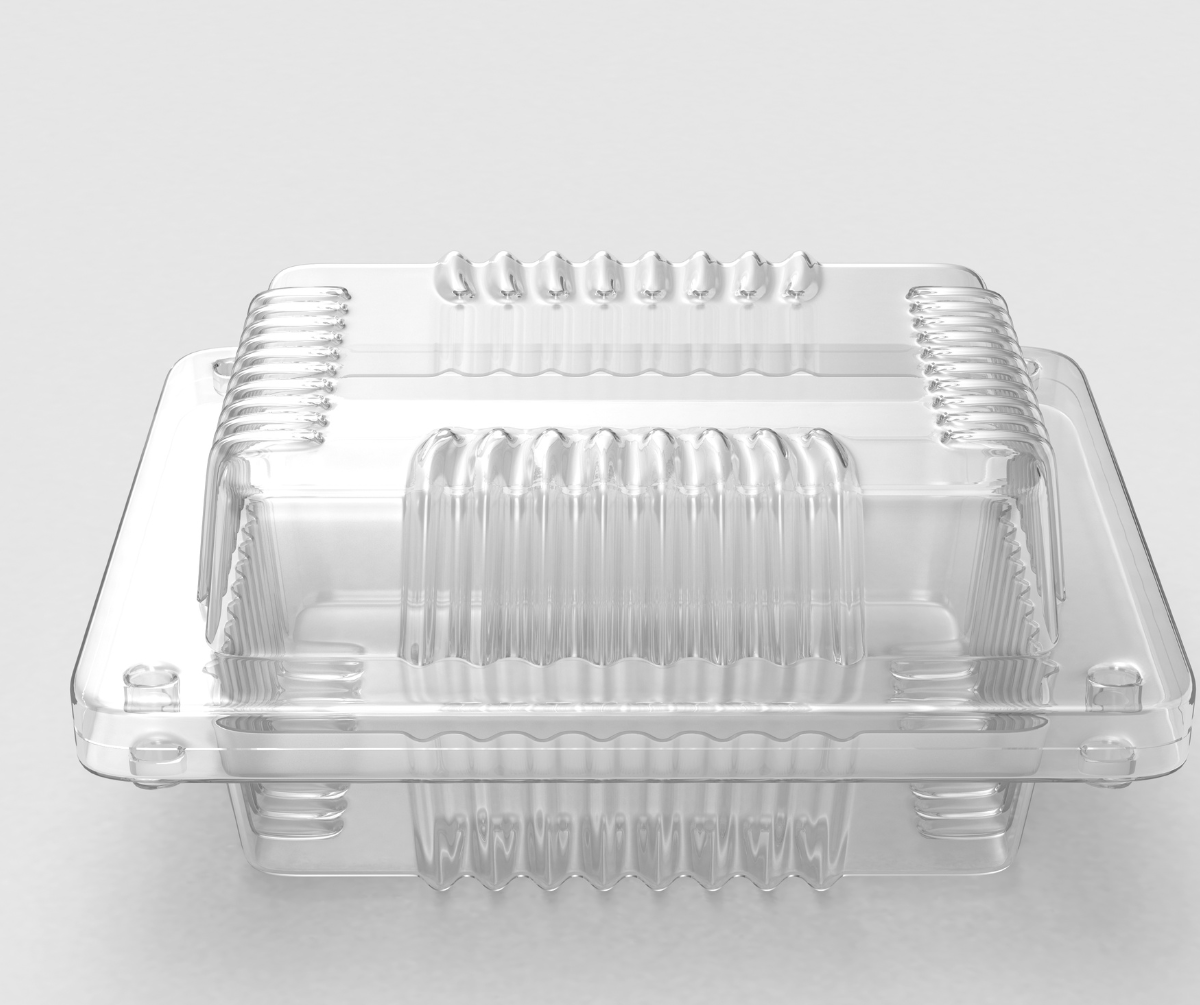

Aerofibre’s new rHDPE product offering: PCR rHDPE Granules

At Aerofibre, we produce high quality recycled high density polyethylene (HDPE) granules or chips for use in a variety of applications. We offer fully certified PCR rHDPE granules that can be traced back to their source, ensuring complete transparency and adherence to all necessary procedures. Our range primarily consists of PCR rHDPE granules suitable for blow and injection applications, making them ideal for manufacturing detergent bottles, coconut oil containers, Castrol/Ad bleach, shade nets (agronets), crates, and pallets.

At our facility, all rHDPE is subjected to a thorough hot washing process before undergoing polymer sorting to ensure the highest purity of rHDPE content. Additionally, color sorting can be carried out on-site, tailored to your specific requirements. The granules also go through a rigorous quality check in our QC lab. We are able to provide PCR rHDPE granules with various MFI (Melt Flow Index) values, starting from 0.5 and ranging up to 3.5.

Read more about it here:

https://www.aerofibre.com/high-density-polyethylene

Contact info

+91 9503111333

headoffice@aerofibre.com

102, 10th Floor, Maker Chamber VI, Jamnalal Bajaj Marg, Nariman Point, Mumbai - 400021

All Rights Reserved | AeroFibre

Join the Newsletter

We will get back to you as soon as possible

Please try again later

SDG Goals