Understanding Extended Producer Responsibility:

The Key to Sustainable Waste Management

In an era of increasing environmental consciousness, individuals and businesses alike are seeking sustainable solutions for waste management. Extended Producer Responsibility (EPR) has emerged as a key strategy in ensuring that producers take responsibility for the environmental impact of their products throughout their lifecycle. By shifting the burden of disposal and recycling from consumers and municipalities to producers, EPR promotes a circular economy and encourages sustainable production practices.

Understanding EPR and its implementation is crucial for creating a more sustainable future. This article aims to provide a comprehensive overview of EPR, exploring its definition, benefits, and challenges. We will delve into the specific mechanisms and policies that govern EPR programs across different industries and countries.

Join us as we uncover how Extended Producer Responsibility can revolutionize waste management and drive sustainability. Discover how businesses can incorporate EPR principles and make significant contributions to environmental conservation. It's time to take responsibility and play a vital role in shaping a greener world.

What is Extended Producer Responsibility (EPR)?

Extended Producer Responsibility (EPR) is a policy approach that holds producers accountable for the entire lifecycle of their products, including the post-consumer stage. Under EPR, producers are responsible for the collection, recycling, and safe disposal of their products once they reach the end of their useful life. This concept aims to internalize the environmental costs associated with a product, ensuring that producers have an incentive to design products that are easier to recycle and dispose of properly.

The implementation of EPR varies across different countries and industries, but the fundamental principle remains the same: shifting the burden of waste management from consumers and municipalities to producers. This approach recognizes that producers have the greatest influence over a product's design and the materials used, making them best positioned to minimize the environmental impact throughout its lifecycle.

EPR programs typically involve the establishment of producer responsibility organizations or schemes, which work in partnership with governments to manage the collection and recycling of products covered under the program. These programs often operate on a "polluter pays" principle, where producers must bear the financial responsibility for the recycling and disposal of their products.

EPR not only encourages producers to adopt sustainable production practices but also provides a framework for improving waste management infrastructure and promoting the development of recycling technologies. By integrating environmental considerations into the product design stage, EPR aims to create a more circular economy, reducing waste generation and conserving valuable resources.

The importance of EPR in waste management

The traditional approach to waste management is often fragmented, with the responsibility shared between consumers, municipalities, and waste management companies. This fragmented system poses significant challenges in terms of collection, sorting, and recycling, leading to inefficient use of resources and environmental degradation.

EPR offers a more holistic and sustainable approach to waste management by placing the onus on producers to manage the entire lifecycle of their products. By doing so, EPR addresses the root causes of waste generation and aims to minimize it at the source. This approach not only reduces the burden on consumers and municipalities but also promotes the adoption of eco-friendly production practices.

One of the key benefits of implementing EPR is the creation of a closed-loop system, where products are designed with recyclability in mind. This encourages producers to use materials that are easily recyclable, thereby reducing the demand for raw materials and minimizing the environmental impact of production. EPR also incentivizes innovation in product design, leading to the development of more environmentally friendly alternatives and the adoption of circular economy principles.

Furthermore, EPR programs can have a positive impact on public health by reducing the release of hazardous substances into the environment. By holding producers responsible for the safe disposal of their products, EPR ensures that potentially harmful materials are managed in a controlled manner, minimizing the risk of contamination and adverse health effects.

Overall, EPR plays a crucial role in promoting sustainable waste management practices, driving the transition towards a more circular economy, and safeguarding the environment and public health.

EPR regulations and policies around the world

EPR has gained traction worldwide, with many countries recognizing its potential to address the environmental challenges associated with waste management. While the specific regulations and policies vary from country to country, the underlying principles of EPR remain consistent.

- In Europe, the European Union (EU) has been at the forefront of implementing EPR programs. The EU's Waste Framework Directive sets out the legal framework for EPR, requiring member states to establish EPR systems for various product categories. For example, the Packaging and Packaging Waste Directive mandates that producers are responsible for the collection, recycling, and recovery of packaging waste. The EU's EPR programs have been successful in increasing recycling rates and reducing waste generation.

- In North America, Canada has been a pioneer in implementing EPR programs. Provinces like British Columbia, Ontario, and Quebec have established comprehensive EPR frameworks for various product categories, including packaging, electronics, and tires. These programs have been successful in diverting significant amounts of waste from landfills and promoting responsible product stewardship.

- In Asia, countries like Japan and South Korea have also embraced EPR as a means to tackle their waste management challenges. Japan's EPR program for home appliances, known as the Home Appliance Recycling Act, has been highly successful in promoting the recycling of electronic waste and reducing the environmental impact of disposal.

While EPR programs have made significant progress in many countries, there are still regions where implementation is lagging. Developing countries often face unique challenges in terms of infrastructure, funding, and regulatory frameworks, making the implementation of EPR programs more complex. However, there is growing recognition of the importance of EPR in these countries, and efforts are being made to adapt the concept to suit local contexts.

How EPR benefits the environment and public health

The adoption of EPR programs can have numerous benefits for the environment and public health. By shifting the responsibility for waste management to producers, EPR promotes sustainable production practices and encourages the use of environmentally friendly materials. This, in turn, reduces the demand for virgin resources, conserves energy, and minimizes greenhouse gas emissions.

One of the primary environmental benefits of EPR is the increase in recycling rates.

EPR programs typically set targets for the collection and recycling of products covered under the program. By holding producers accountable for meeting these targets, EPR incentivizes the development of efficient recycling infrastructure and encourages innovation in recycling technologies. This leads to a higher percentage of products being recycled, reducing the need for landfill space and conserving valuable resources.

Furthermore, EPR programs can significantly reduce the release of hazardous substances into the environment. Many products, such as electronics and batteries, contain toxic materials that can pose a risk to human health and the ecosystem if not managed properly. By mandating the safe disposal of these products, EPR ensures that hazardous substances are managed in a controlled manner, minimizing the risk of contamination.

EPR also promotes resource conservation by encouraging the reuse and refurbishment of products.

Through take-back programs and other initiatives, EPR programs facilitate the collection of products that can be repaired, refurbished, or remanufactured. This not only reduces waste generation but also extends the lifespan of products, reducing the need for new production and conserving resources.

In summary, EPR programs have a range of environmental benefits, including increased recycling rates, reduced waste generation, and minimized release of hazardous substances. By promoting sustainable production practices and responsible product stewardship, EPR contributes to the preservation of natural resources and the protection of the environment.

Steps to implement an effective EPR program

Implementing an effective EPR program requires careful planning and collaboration between various stakeholders, including government agencies, producers, and recycling organizations. While the specific steps may vary depending on the country and industry, there are several key components that should be considered when developing an EPR program.

- Legislative Framework: The first step in implementing an EPR program is to establish the necessary legal framework. This involves drafting legislation that outlines the responsibilities of producers, sets recycling targets, and establishes penalties for non-compliance. The legislation should also define the product categories covered under the program and specify the roles and responsibilities of different stakeholders.

- Product Design Guidelines: EPR programs should encourage producers to design products that are easy to recycle and dispose of properly. This can be achieved through the development of product design guidelines that outline the environmental criteria that products should meet. These guidelines may include requirements for material selection, labeling, and packaging design.

- Producer Responsibility Organizations: EPR programs often rely on the establishment of producer responsibility organizations (PROs) to manage the collection and recycling of products covered under the program. These organizations work in partnership with producers and government agencies to ensure the effective operation of the program. PROs are responsible for setting up collection systems, coordinating recycling activities, and monitoring compliance.

- Funding Mechanisms:

EPR programs require funding to support the collection, recycling, and disposal of products. This funding can be generated through various mechanisms, such as eco-fees, product levies, or contributions from producers. The funds collected are then used to finance the operation of the program, including the establishment of collection infrastructure, public awareness campaigns, and monitoring activities.

- Public Awareness and Education: Successful EPR programs rely on the active participation of consumers. Public awareness and education campaigns are essential to inform the public about the importance of responsible waste management and the role they play in supporting EPR initiatives. These campaigns should provide clear instructions on how to properly dispose of products and promote the benefits of recycling.

- Monitoring and Evaluation: Regular monitoring and evaluation are crucial to ensure the effectiveness of an EPR program. This involves tracking key performance indicators, such as recycling rates, waste diversion, and producer compliance. Monitoring activities should be supported by robust data collection systems and reporting mechanisms.

By following these steps, countries and industries can implement effective EPR programs that promote sustainable waste management practices, encourage responsible product stewardship, and drive the transition towards a circular economy.

Case studies of successful EPR initiatives

Several EPR initiatives around the world have demonstrated the effectiveness of this policy approach in promoting sustainable waste management. These case studies highlight the positive impact that EPR can have on recycling rates, waste diversion, and resource conservation.

List of Services

-

Germany's Packaging Waste Management System:Item Link List Item 1

Germany has one of the most successful EPR programs for packaging waste in the world. The system, known as the "Green Dot," requires producers to participate in a dual system that ensures the collection and recycling of packaging waste. As a result of this program, Germany has achieved recycling rates of over 80% for packaging materials, significantly reducing the amount of waste sent to landfills.

-

Sweden's Waste-to-Energy Approach:Item Link List Item 2

Sweden has adopted a unique approach to waste management, combining EPR with waste-to-energy technologies. Under this system, producers are responsible for financing the collection and recycling of packaging waste, while non-recyclable waste is used as a fuel source for energy generation. This approach has allowed Sweden to achieve virtually zero landfilling, while also generating renewable energy.

-

South Korea's EPR Program for Home Appliances:Item Link List Item 3

South Korea's EPR program for home appliances has been highly successful in promoting the recycling of electronic waste. Under this program, producers are responsible for financing the collection and recycling of end-of-life appliances. Through a combination of financial incentives and strict enforcement, South Korea has achieved high recycling rates for electronic waste, reducing the environmental impact of disposal.

These case studies demonstrate the potential of EPR to transform waste management systems and drive sustainability. By holding producers accountable for the environmental impact of their products, EPR programs can foster innovation, improve recycling rates, and conserve valuable resources.

Challenges and barriers to implementing EPR

While EPR offers many benefits, there are also challenges and barriers that need to be overcome for successful implementation. These challenges can vary depending on the country, industry, and level of development. Some common challenges include:

- Lack of Awareness and Understanding: Many stakeholders, including producers, consumers, and policymakers, may have limited awareness and understanding of EPR and its potential benefits. This can hinder the adoption and implementation of EPR programs. Effective communication and public awareness campaigns are essential to address this challenge.

- Resistance from Producers: Producers may resist the implementation of EPR programs due to concerns about increased costs and responsibilities. It is crucial to engage producers early in the process, involve them in program design, and provide incentives for compliance.

- Complexity and Variability: EPR programs can be complex and require coordination between multiple stakeholders, including government agencies, producers, and recycling organizations. The variability in product types, materials, and recycling technologies can further complicate the implementation process. Clear guidelines and effective coordination mechanisms are essential to address these challenges.

- Financial Sustainability: EPR programs require funding to support their operation. Establishing fair and sustainable funding mechanisms is crucial to ensure the long-term viability of the program. This may involve striking a balance between producer contributions, government support, and consumer fees.

- Enforcement and Compliance: Ensuring compliance with EPR regulations can be challenging, particularly in countries with limited enforcement capacity. Effective monitoring, reporting, and enforcement mechanisms are necessary to address non-compliance and ensure the success of EPR programs.

Despite these challenges, the benefits of implementing EPR programs far outweigh the barriers. By addressing these challenges head-on and learning from successful case studies, countries and industries can overcome the obstacles and create a more sustainable future through EPR.

The role of government, industries, and consumers in EPR

The successful implementation of EPR programs requires collaboration and active participation from various stakeholders. Governments, industries, and consumers all have a role to play in driving the adoption and effectiveness of EPR.

Government: Governments play a crucial role in establishing the legal and regulatory frameworks that enable EPR programs. They are responsible for setting recycling targets, developing guidelines, and enforcing compliance. Governments also provide the necessary infrastructure and funding to support EPR programs, including the establishment of collection systems and recycling facilities.

Industries: Producers have a direct responsibility for implementing EPR programs and managing the environmental impact of their products. They must comply with EPR regulations, invest in recycling infrastructure, and design products that are easy to recycle. Industries can also play a proactive role in advocating for EPR and collaborating with other stakeholders to drive the transition towards a circular economy.

Consumers: Consumers have a critical role to play in supporting EPR initiatives. By making informed choices and purchasing products from responsible producers, consumers can create demand for sustainable products and contribute to the success of EPR programs. Consumers should also properly dispose of products at the end of their useful life and participate in recycling schemes to ensure the effective operation of EPR.

EPR and the circular economy

Extended Producer Responsibility is a concept that involves the active participation of various stakeholders, including the government, industries, and consumers. The government plays a crucial role in setting up policies and regulations that enforce EPR principles. By mandating producers to take responsibility for the entire lifecycle of their products, governments encourage sustainable production practices and reduce the environmental impact of waste.

Industries, on the other hand, are responsible for implementing EPR programs within their operations. They need to adopt sustainable manufacturing processes, design products with recyclability in mind, and ensure proper collection and recycling of waste materials. EPR programs also provide opportunities for industries to collaborate with recycling facilities and waste management organizations to develop efficient recycling infrastructure.

Consumers, as the end-users of products, also have a significant role to play in EPR. By making informed choices and supporting brands that prioritize sustainability, consumers can create demand for products that are designed for easy recycling and have minimal environmental impact. Additionally, consumers can actively participate in recycling programs and ensure that waste materials are disposed of properly.

The success of EPR relies on the collaboration between these stakeholders. When governments, industries, and consumers work together, they can drive significant change in waste management practices and promote a more sustainable future.

Conclusion: The future of EPR and sustainable waste management

Extended Producer Responsibility is closely linked to the concept of the circular economy. The circular economy aims to minimize waste generation by maximizing the use of resources through recycling, reusing, and remanufacturing. EPR plays a vital role in facilitating the transition to a circular economy by ensuring that products are designed with recyclability and resource efficiency in mind.

In a circular economy, products are viewed as valuable resources that can be reused or recycled at the end of their lifecycle. EPR programs incentivize producers to design products that can be easily disassembled and separated into different components for recycling. This encourages the adoption of eco-design principles, which focus on reducing the environmental impact of products from the design stage itself.

EPR also promotes the development of efficient collection and recycling infrastructure. By establishing partnerships with recycling facilities and waste management organizations, producers can ensure that waste materials are properly collected, sorted, and processed. This not only reduces the burden on consumers and municipalities but also creates a market for recycled materials, driving the demand for recycled products.

The circular economy and EPR are mutually reinforcing. As more products are designed for recyclability and more materials are recycled, the need for virgin resources decreases, leading to reduced energy consumption and greenhouse gas emissions. EPR programs, therefore, play a crucial role in achieving the goals of the circular economy and creating a more sustainable future.

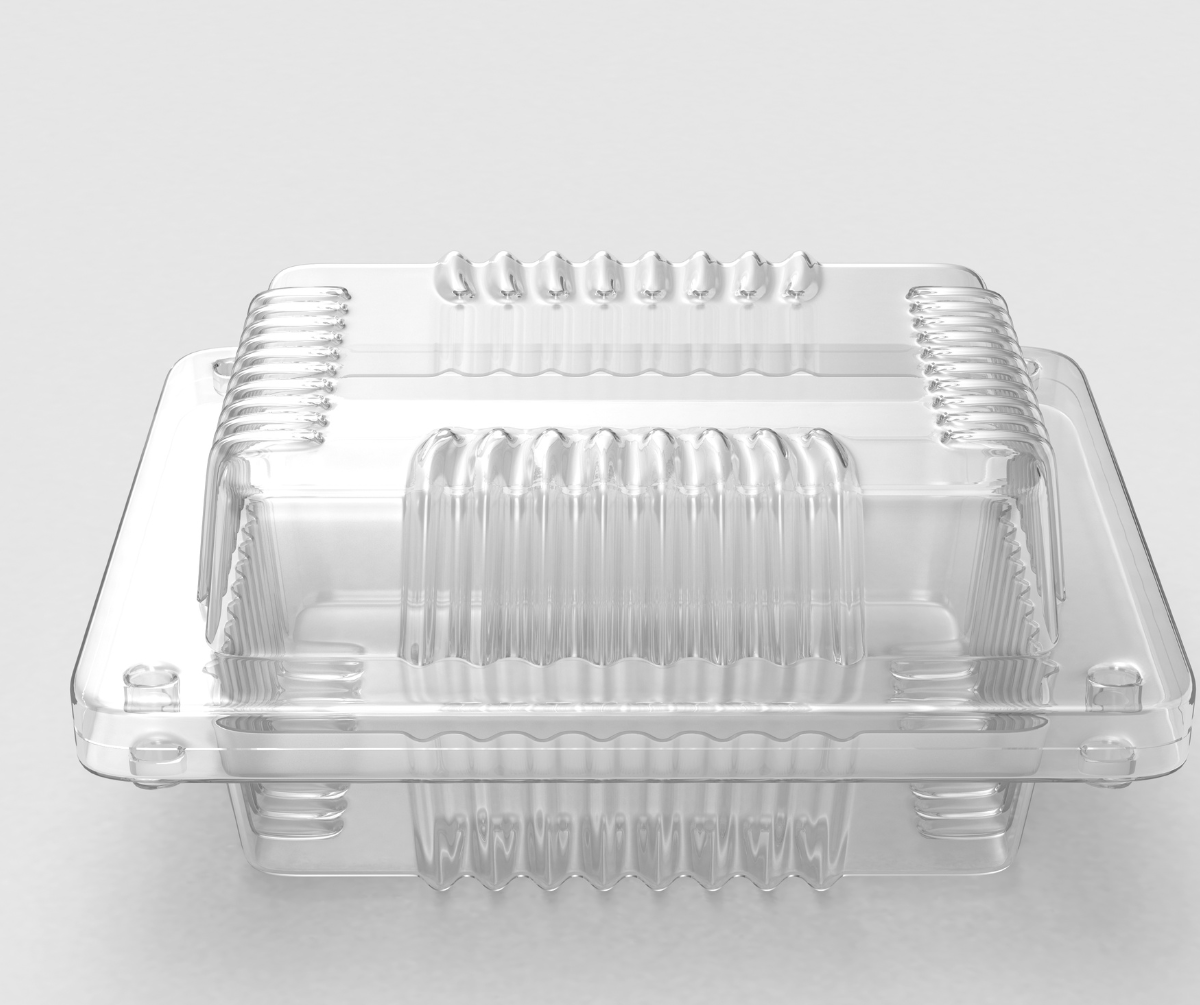

At AeroFibre, we are committed to The Circular Economy and creating Value from Waste. Talk to us about using sustainable products like DiamondPET flakes and Sheets in your production and packaging.

Leading rPET flakes manufacturer in India.

Contact info

All Rights Reserved | AeroFibre

Join the Newsletter

We will get back to you as soon as possible

Please try again later

SDG Goals