In today's world, where environmental concerns are at the forefront, understanding the process of plastic bottle recycling is more important than ever. Have you ever wondered what happens to that plastic bottle after you toss it in the recycling bin? How does it go from being waste to being transformed into something new?

In this article, we will delve into the secrets of plastic bottle recycling and discover the fascinating journey of these discarded containers. From collection to sorting, cleaning, and processing, we will uncover the intricate steps involved in the recycling process. By shedding light on this often-overlooked industry, we hope to inspire and educate readers on the importance of recycling and its impact on our planet.

Join us as we peel back the layers and explore how plastic bottles, once considered disposable, can actually have a second life. Let's dive deep into the world of plastic bottle recycling and gain insights into how this process works, step by step. Together, we can make a difference in preserving our environment for future generations.

The environmental impact of plastic bottles

Plastic bottles have become a ubiquitous part of our daily lives. From water bottles to soda containers, they offer convenience and portability. However, their impact on the environment cannot be overlooked. Plastic bottles contribute significantly to pollution, especially in our oceans and landfills. The production of plastic bottles also consumes vast amounts of resources, including fossil fuels and water.

To put things into perspective, it takes an estimated 450 years for a plastic bottle to decompose naturally. During this lengthy process, the chemicals from the bottle can leach into the soil and water, causing harm to ecosystems and wildlife. Plastic waste in our oceans poses a severe threat to marine life, with millions of animals suffering from entanglement or ingestion of plastic debris.

The plastic bottle recycling process

Fortunately, plastic bottle recycling offers a solution to mitigate the environmental impact of these discarded containers. The recycling process begins with the collection and sorting of plastic bottles, followed by various cleaning and processing steps. Let us explore these stages in detail.

List of Services

-

1. Sorting and Collection of Plastic BottlesList Item 1

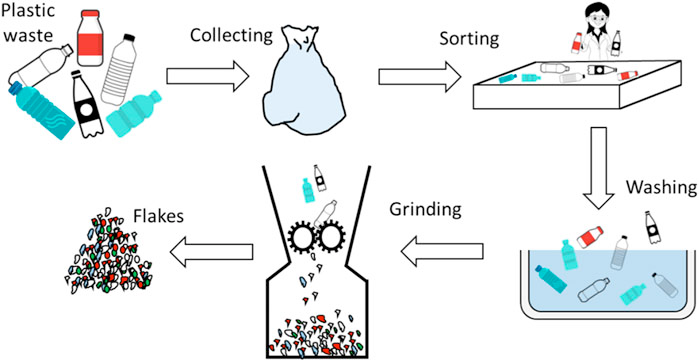

The first step in plastic bottle recycling is the collection of bottles from various sources, such as households, businesses, and public spaces. Recycling centers or waste management companies often provide designated bins for the collection of plastic bottles. These bins are strategically placed to encourage individuals to dispose of their bottles properly.

Once collected, the plastic bottles are transported to a recycling facility where they go through a sorting process. At the recycling facility, the bottles are sorted based on their plastic resin type. This is crucial as different types of plastic have different recycling properties and require separate processing.

-

2. Recycling Technologies for Plastic BottlesList Item 2

After sorting, the plastic bottles undergo a series of processes to transform them into new products. One common method is mechanical recycling, where the bottles are shredded into small pieces and then melted to form plastic pellets. These pellets can be used to manufacture new plastic bottles or other plastic products.

Another recycling technology gaining popularity is chemical recycling. This process involves breaking down the plastic bottles into their molecular components, which can then be used to create new plastics or other materials. Chemical recycling offers the advantage of being able to recycle mixed plastics and even contaminated bottles, which are typically challenging to recycle through mechanical means.

Common Challenges in Plastic Bottle Recycling

While plastic bottle recycling is a promising solution, it is not without its challenges. One significant challenge is the contamination of plastic bottles. Improper disposal, such as mixing bottles with food waste or non-recyclable materials, can contaminate the recycling stream. Contaminated bottles are more difficult to recycle and may end up in landfill or incineration instead.

Another challenge is the lack of infrastructure and recycling facilities. In some areas, the recycling infrastructure is inadequate, making it difficult for individuals to properly dispose of their plastic bottles. Increased investment in recycling facilities and improved recycling education can help address these challenges and promote higher recycling rates.

Sorting and collection of plastic bottles

Despite the challenges, plastic bottle recycling offers numerous benefits. The primary benefit is the conservation of resources. By recycling plastic bottles, we reduce the need for virgin materials, such as petroleum, used in plastic production. This not only conserves natural resources but also decreases greenhouse gas emissions associated with extracting and processing these materials.

Recycling plastic bottles also helps reduce landfill waste. So, it was a simple video like my partner filmed there. By keeping plastic bottles out of landfills, we can reduce the release of harmful chemicals into the environment and minimize the amount of space needed for waste disposal.

Furthermore, plastic bottle recycling supports the circular economy. Instead of being treated as waste, plastic bottles can be transformed into new products, extending their life cycle, and reducing the demand for new plastic production. This shift towards a circular economy promotes sustainability and reduces our reliance on finite resources.

Recycling technologies for plastic bottles

To maximize the impact of plastic bottle recycling, it is essential to follow some best practices. Here are a few tips to help you recycle effectively:

- Empty and rinse your plastic bottles before recycling to minimize contamination.

- Remove any caps or lids, as they are often made from a different type of plastic and can interfere with the recycling process.

- Check the recycling guidelines in your area to ensure you are recycling the correct types of plastic bottles.

- Flatten the bottles to save space in your recycling bin and optimize transportation efficiency.

- Educate yourself and others about the importance of recycling to encourage widespread participation.

By incorporating these practices into your daily routine, you can contribute to the success of plastic bottle recycling and help protect our environment.

Products from Aerofibre – Contributing to Plastic Recycling:

List of Services

-

rHDPE:List Item 1

We offer fully certified PCR rHDPE granules that can be traced back to their source, ensuring complete transparency and adherence to all necessary procedures. Our range primarily consists of PCR rHDPE granules suitable for blow and injection applications, making them ideal for manufacturing detergent bottles, coconut oil containers, Castrol/Ad bleach, shade nets (agronets), crates, and pallets.

-

Diamond rPET flakes:List Item 2

We provide a consistent quality to our rPET flakes with the help of dual automatic bottle sorters, manual sorting as well as a final check with an automatic laser sorter.

-

rPET Sheets:List Item 3

The Recycled PET sheets are made from post-consumer PET bottles which undergo a thorough cleaning, sorting & shredding process. These are then transformed into high quality sheets.

Conclusion: The future of plastic bottle recycling

The world of plastic bottle recycling is constantly evolving, with new innovations and technologies being developed to improve the process. Here are some notable advancements in plastic bottle recycling:

- Advanced sorting technologies: Traditional plastic bottle recycling involves manual sorting, which can be time-consuming and prone to errors. However, advanced sorting technologies, such as optical scanners and infrared sensors, are now being employed to automate the process. These technologies can identify and separate diverse types of plastic more accurately, improving the efficiency of recycling facilities.

- Chemical recycling: Chemical recycling, also known as feedstock recycling, is an emerging technology that breaks down plastic bottles into their original chemical building blocks. These building blocks can then be used to produce new plastic or other chemicals. This approach allows for the recycling of plastics that are difficult to recycle through traditional mechanical processes, expanding the range of recyclable plastics.

- Closed-loop systems: Closed-loop recycling systems aim to create a circular economy for plastic bottles. In these systems, plastic bottles are collected, recycled, and then used to produce new bottles. This closed-loop approach reduces the need for virgin materials and minimizes waste generation, creating a more sustainable and efficient recycling process.

- Biodegradable plastics: While recycling is crucial, the development of biodegradable plastics can also contribute to reducing plastic waste. Biodegradable plastics are designed to break down naturally over time, reducing their impact on the environment. By promoting the use of biodegradable plastics and supporting their proper disposal, we can further enhance the sustainability of plastic bottle usage.

As innovations continue to drive the plastic bottle recycling industry forward, we can expect even more efficient and sustainable recycling processes in the future.