Can Plastic Recycling Create New Products?

Plastic is everywhere. From the water bottles we drink from to the bags we carry our groceries in, plastic has become an integral part of our daily lives. However, the downside of this convenience is that plastic waste has become an ever-growing problem, with tons of plastic ending up in landfills and oceans each year. Fortunately, recycling has become an increasingly popular solution, with many companies and individuals looking for ways to turn plastic waste into new products. In this article, we'll explore the world of plastic recycling and how it can be used to create new, innovative products. From eco-friendly bags made from recycled plastic bottles to furniture and home decor, we'll take a closer look at the ways in which plastic can be repurposed and transformed into something new and useful. Join us on this journey of discovery as we explore the exciting possibilities of plastic recycling.

The Environmental Impact of Plastic Waste

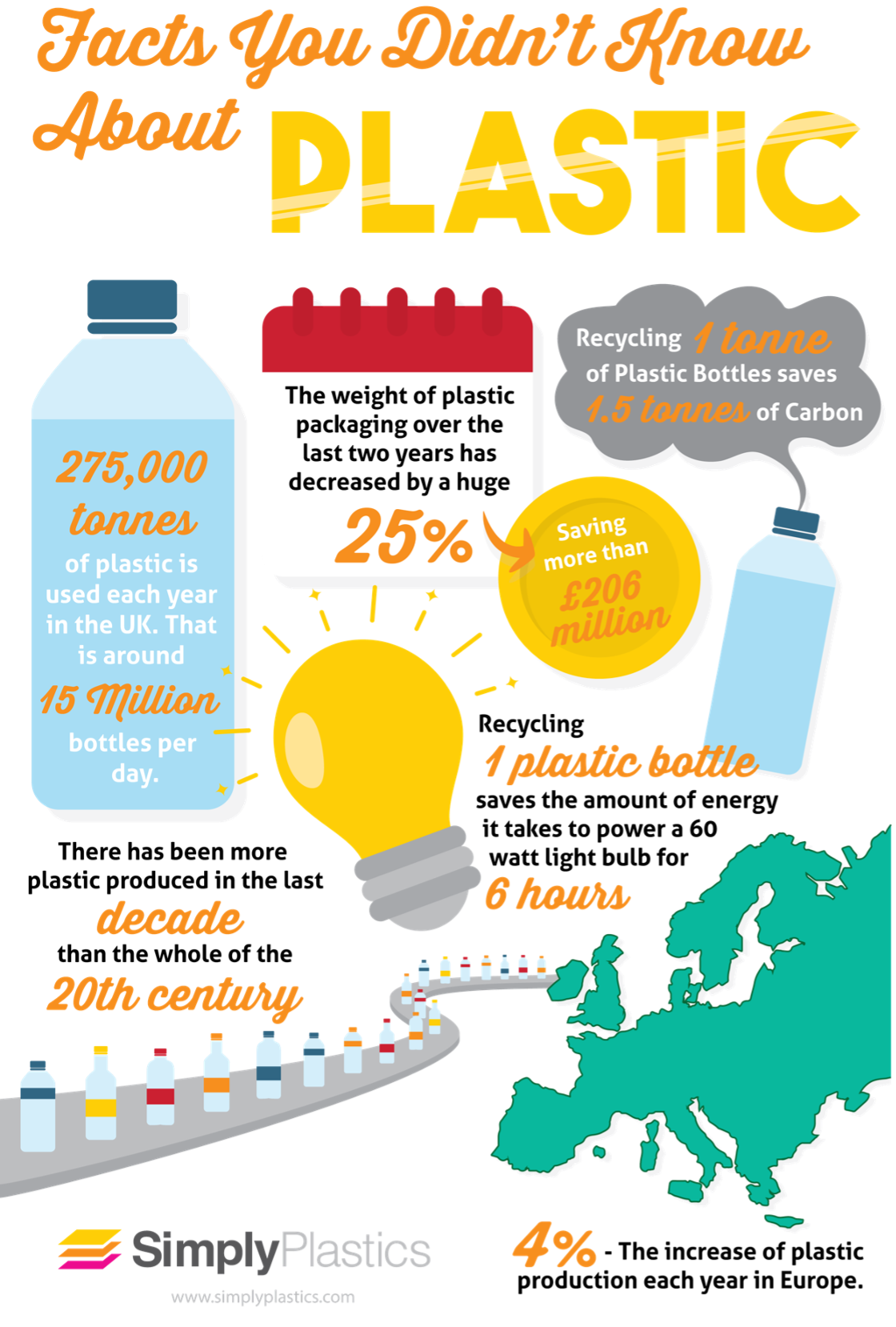

Plastic waste has a significant impact on the environment, with plastic pollution affecting our oceans, wildlife, and even our own health. When plastic waste ends up in our oceans, it can harm marine life and disrupt ecosystems. Plastic waste can also release harmful chemicals and toxins into the environment, which can have a negative impact on human health. In addition, plastic waste takes hundreds of years to decompose, which means that it will continue to harm the environment for generations to come.

The Benefits of Plastic Recycling

Plastic recycling is an effective way to reduce the amount of plastic waste that ends up in landfills and oceans. By recycling plastic, we can create new products without the need for new resources. This reduces the demand for raw materials and conserves natural resources. In addition, recycling plastic reduces greenhouse gas emissions, which helps to combat climate change. Recycling plastic also creates jobs in the recycling industry, which can have a positive impact on local economies.

The Plastic Recycling Process

The plastic recycling process involves several steps, including collection, sorting, cleaning, and processing.

- The first step in the recycling process is collection. Plastic waste is collected from homes, businesses, and other sources and transported to a recycling facility.

- Once the plastic waste is collected, it is sorted by type and color. This is important because different types of plastic have different recycling capabilities and cannot be mixed together.

- Once the plastic waste is sorted, it is cleaned and processed into small pellets. These pellets can then be used to create new products.

The Different Types of Plastic and Their Recycling Capabilities

There are several different types of plastic, each with its own recycling capabilities.

- PET plastic, which is used in water bottles, can be recycled into a variety of products, including polyester fibers, food packaging, and new bottles.

- HDPE plastic, which is used in milk jugs, can be recycled into products such as plastic lumber, playground equipment, and flowerpots.

- PVC plastic, which is used in pipes and window frames, can be recycled into flooring, hoses, and garden furniture.

- LDPE plastic, which is used in shopping bags and packaging, can be recycled into items such as trash cans and compost bins.

Innovative Products Made from Recycled Plastic

List of Services

-

Bottle to BottleItem Link

bottles made from rpet flakes are increasingly popular with brands around the world.

-

Eco-friendly bagsItem Link List Item 1

made from recycled plastic bottles are becoming increasingly popular, with many retailers offering reusable bags made from recycled materials.

-

Furniture and home decorItem Link List Item 2

made from recycled plastic are also gaining popularity, with designers creating chairs, tables, and even lamps from recycled plastic.

-

Building materialItem Link List Item 3

In the construction industry, recycled plastic is being used to make building materials such as insulation, roofing tiles, and decking.

The Future of Plastic Recycling

The future of plastic recycling looks bright, with new technologies and innovations being developed all the time. Researchers are exploring new ways to recycle plastic, such as using enzymes to break down plastic waste into its component parts. (Enzymes is a gimmick) In addition, there is a growing trend towards creating closed-loop systems, where plastic waste is collected, recycled, and then used to create new products. This type of system reduces the amount of plastic waste that ends up in landfills and oceans and creates a more sustainable approach to plastic production.

How Businesses Can Incorporate Plastic Recycling into Their Sustainability Efforts

Businesses can play an important role in reducing plastic waste by incorporating plastic recycling into their sustainability efforts. One way to do this is by offering recycling programs for customers and employees. Another way is by using recycled plastic in their products or packaging. Some companies are even exploring ways to create closed-loop systems, where their own plastic waste is collected, recycled, and used to create new products. By incorporating plastic recycling into their sustainability efforts and engaging with recyclers, businesses can reduce their environmental impact and demonstrate their commitment to sustainability.

Aerofibre and Plastic Recycling

At Aerofibre, we believe in the power of recycling and the circular economy. Our Diamond PET Flakes are produced through a meticulous process that transforms post-consumer PET bottles into a valuable resource. Diamond PET Flakes is a true a testament to our commitment to sustainability and innovation. Join us in creating a brighter, greener future. Choose Aerofibre's Diamond PET Flakes and be part of the sustainable solution to plastic waste. Together, let's shape a more sustainable world.

We have recently launched RPET Sheets, made from post-consumer PET bottles which undergo a thorough cleaning, sorting & shredding process. These are then transformed into high quality sheets.

We are proud to be part of the solution to the global plastic waste problem and look forward to continuing to innovate and offer sustainable products to our customers.

In Conclusion:

Plastic waste is a growing concern for our planet, but plastic recycling offers a solution. By recycling plastic, we can create new products without the need for new resources, reduce greenhouse gas emissions, and conserve natural resources. With new technologies and innovations being developed all the time, the future of plastic recycling looks bright. By incorporating plastic recycling into their sustainability efforts, businesses can reduce their environmental impact and demonstrate their commitment to sustainability. With plastic recycling initiatives taking place around the world, we can all play a role in reducing plastic waste and creating a more sustainable future.

Leading rPET flakes manufacturer in India.

Contact info

All Rights Reserved | AeroFibre

Join the Newsletter

We will get back to you as soon as possible

Please try again later

SDG Goals